Pneumatic fittings play an essential role in a variety of systems, both industrial and automotive.

They are responsible for establishing secure and efficient links between pneumatic system components, which use compressed air to operate.

Whether in a factory production line or in an automotive vehicle, pneumatic connections are crucial to ensure the proper and safe operation of systems.

In this article, we will discuss the different types of pneumatic connections, their various applications, and provide guidance on how to choose the best option for your needs.

If you are involved with pneumatic systems, whether in an industrial or automotive environment, understanding the characteristics of these connections can make all the difference in the efficiency and safety of your projects.

So, follow this article and stay informed of all the necessary information!

What are pneumatic fittings?

Pneumatic fittings are devices designed to connect components of pneumatic systems. They allow compressed air to circulate efficiently between the parts of the system, ensuring that the necessary pressures are maintained and that control signals are transmitted correctly. The use of these connections is fundamental for the proper functioning of automotive and industrial systems, where air control is indispensable for the operation of tools, machines, and devices.

These fittings can be made from different materials, such as steel, brass, plastics, aluminum, and zamac, depending on the pressure, temperature, fluid, and application. In high-pressure systems, for instance, it is necessary for the connections to be made with more robust materials to ensure the system’s durability and safety. In simpler applications, lighter and more flexible materials may be used.

Furthermore, pneumatic fittings have the ability to maintain airtightness, which means preventing leaks, a crucial aspect for system efficiency and operator safety. They also allow for quick adjustments and maintenance, facilitating the upkeep and repair of pneumatic systems.

Fittings are used in various systems, such as pneumatic circuits, automated devices, pneumatic tools, and pressure control systems, and are essential to guarantee the continuity and performance of processes that rely on compressed air.

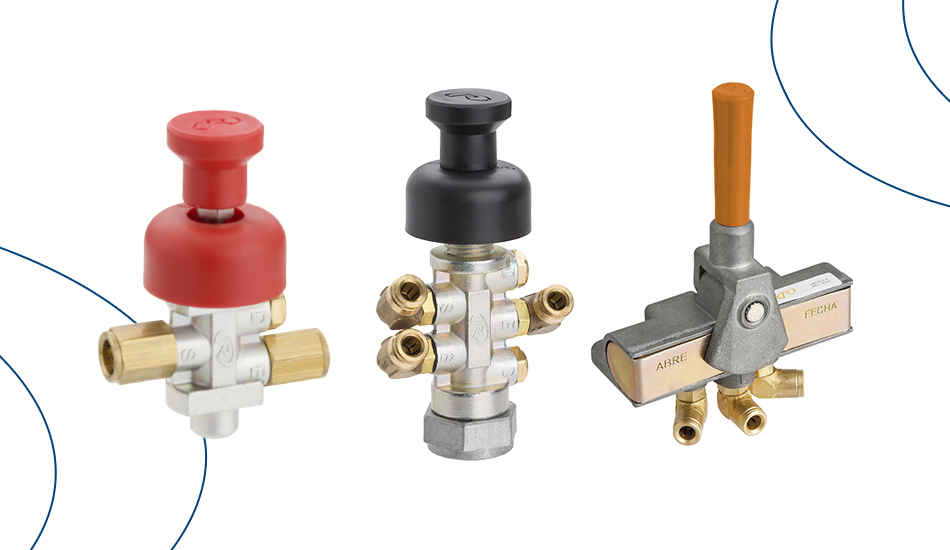

Types of Pneumatic Fittings

Pneumatic fittings can be classified into various types, according to their application, pressure, and technical specifications. Below, we highlight the most common categories, adapted to industrial and automotive needs.

Automotive Pneumatic Connections

In the automotive sector, pneumatic fittings are widely used in compressed air systems for controlling vehicle components that require high performance. These fittings must be resistant to vibration and wear, as vehicles face severe operating conditions.

Automotive pneumatic fittings are designed to ensure an efficient seal and resistance to extreme temperatures and substances like oil and grease, common in the automotive environment. They are used in systems such as air brakes, pneumatic suspensions, and even in emission control devices.

Industrial Pneumatic Fittings

Industrial pneumatic fittings are important for automation and control systems in factories and industries. These systems demand highly durable components to withstand repetitive cycles over long periods. Fittings for industrial applications vary in form and material, but are generally made of metal, such as stainless steel, plastic, or brass, to ensure resistance and longevity.

They are used in a wide range of applications, such as in air flow control systems, pneumatic tools, and in automated assembly and production systems. The efficiency of these connections is fundamental for the continuity of industrial processes and for the safety of operators.

High-Pressure Pneumatic Fittings

High-pressure pneumatic fittings are designed to withstand pressures far superior to those found in conventional systems. They are used in industrial and automotive applications that demand extreme performance, such as in machining systems, high-performance compressors, and resistance testing equipment.

These fittings are made from especially robust materials, such as high-strength steel, to ensure system safety. Furthermore, they are designed to minimize the risk of leaks and failures, which is crucial in environments where safety is a priority.

Applications of Pneumatic Fittings

Pneumatic fittings have a wide range of applications in various sectors, especially in industry and automotive. Below, we detail the main applications of these fittings, highlighting their importance for the efficient and safe operation of systems.

In the Automotive Sector

In the automotive sector, pneumatic fittings are primarily used in compressed air systems, such as in pneumatic tools, air brakes, and air suspensions. They are essential for the proper functioning of heavy vehicles, such as trucks and buses, where compressed air pressure control is necessary for the operation of various vehicle parts.

Furthermore, in automotive assembly and production systems, pneumatic fittings ensure that tools operate safely and with maximum precision, which improves production quality and reduces downtime.

In the Industrial Sector

Pneumatic fittings are vital for automation and control processes in various industrial segments. They are widely used in assembly lines, process control, and automated systems, such as industrial robots, pneumatic tools, and material handling systems.

In industrial environments, where air flow and pressure control are essential, pneumatic fittings ensure the efficiency of machinery and devices. Furthermore, they are also used in temperature and pressure control systems, providing safety and reliability to processes.

In High-Pressure Systems

In some sectors, such as machining and material testing, high-pressure pneumatic fittings are indispensable. They allow compressed air to be used under extreme pressure conditions, which is necessary for conducting resistance tests and for operating high-performance equipment, such as industrial compressors and lubrication systems.

These fittings are designed to withstand high pressures, ensuring that systems operate efficiently and safely, minimizing the risks of failures or accidents.

How to Choose the Best Pneumatic Fitting for Your Needs?

By understanding the essential factors that influence the choice of a pneumatic fittings, the process becomes easier and safer. Below, we list 5 aspects to consider when choosing the best pneumatic fittings:

1. Operating Pressure and Temperature

Operating pressure is one of the critical factors in choosing a pneumatic fitting; however, evaluating the operating temperature and compatibility with the fitting material is fundamental.

Fittings for high-pressure systems need to be more robust and made of materials that can withstand the stress generated by elevated pressures. On the other hand, systems with lower pressures can use simpler fittings with lighter materials. Ensure you choose a fitting capable of withstanding your system’s maximum pressure to guarantee safety and efficiency.

2. Fittings Material

The fittings material is also fundamental in determining its durability and resistance.

Common materials include stainless steel, brass, aluminum, high-resistance plastics, and high-strength zamac.

Stainless steel fittings, for example, are ideal for high-demand industrial systems and corrosion resistance, while brass connections may be more suitable for automotive or low-pressure applications.

3. Type of Application

The type of application also influences the choice of the pneumatic connection.

For automotive systems, for example, connections need to be more compact and resistant to vibrations, in addition to withstanding the extreme operating conditions of vehicles.

Conversely, in industrial systems, connections must be designed to withstand repetitive cycles and operate efficiently in production environments.

Therefore, choose the fitting that best meets the specific demands of your application.

4. Standards and Technical Specifications

When choosing a pneumatic fitting, it is important to verify the standards and technical specifications governing its use. Standards ensure that fittings are produced in accordance with established safety and performance criteria. Make sure that the fittings you choose comply with the conformity requirements of your industry and country.

5. Ease of Installation and Maintenance

Fittings that are easy to install and maintain are always preferable, as they help reduce downtime and operational costs. Quick-fittings and push-to-connect fittings, for example, are an excellent option for systems that require constant maintenance or frequent adjustments.

Conclusion

Pneumatic connections are essential components for the efficient operation of systems that utilize compressed air, both in the industrial and automotive sectors. They play a crucial role in ensuring that systems function safely and efficiently, regardless of the application.

In this article, we have discussed the different types of pneumatic connections, their applications in industrial and automotive sectors, and how to choose the best option for your specific needs. By considering factors such as operating pressure, material, type of application, and technical standards, you can make informed decisions that ensure the longevity and optimal performance of your pneumatic system.

The correct use of connections not only improves system performance but also ensures greater safety and reliability in operations.

At the Time of the Right Choice

For the right choice, consult RGR Pneumatics! Visit our website now and contact our specialized team for assistance.